multicut*-precision tools (basic tools)

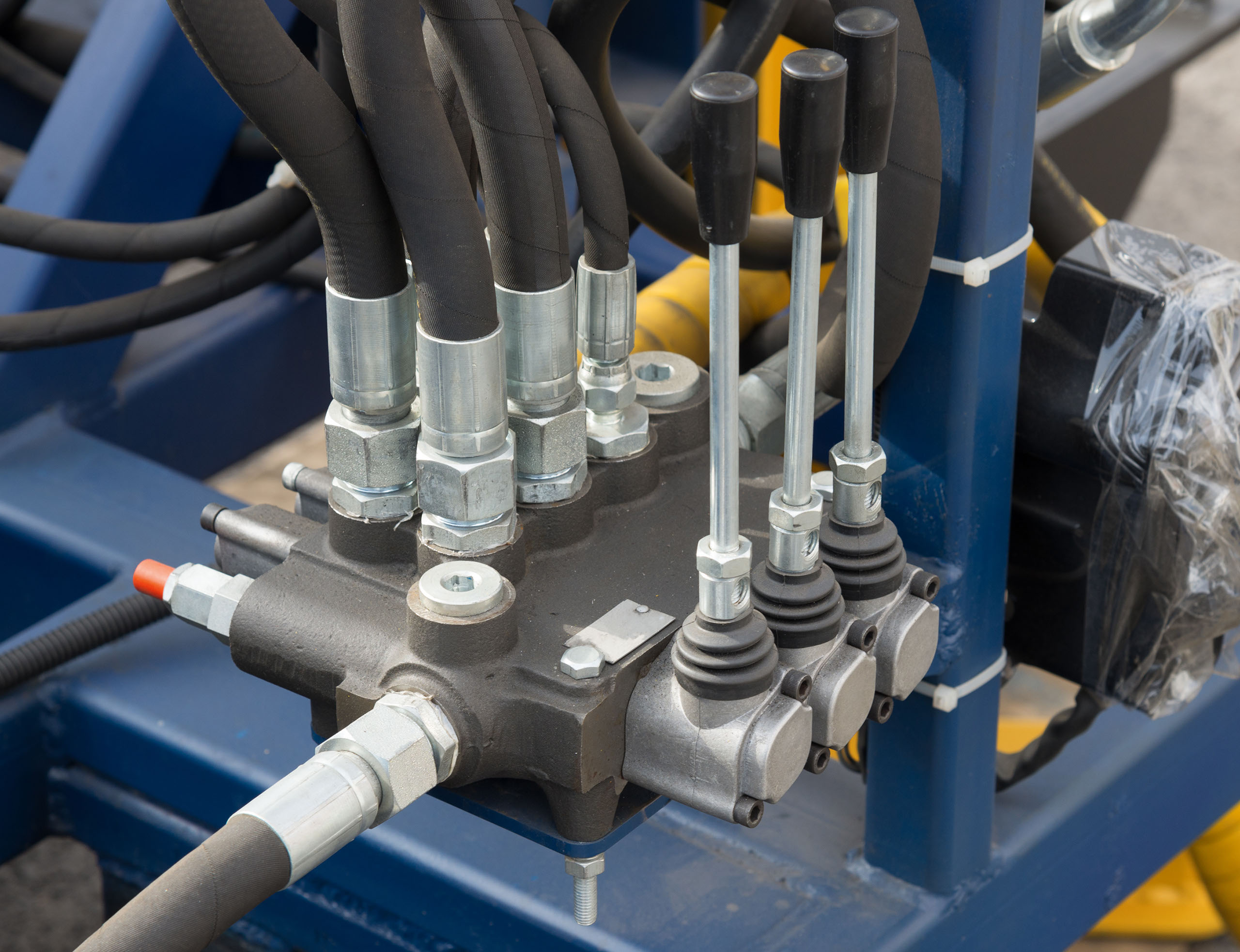

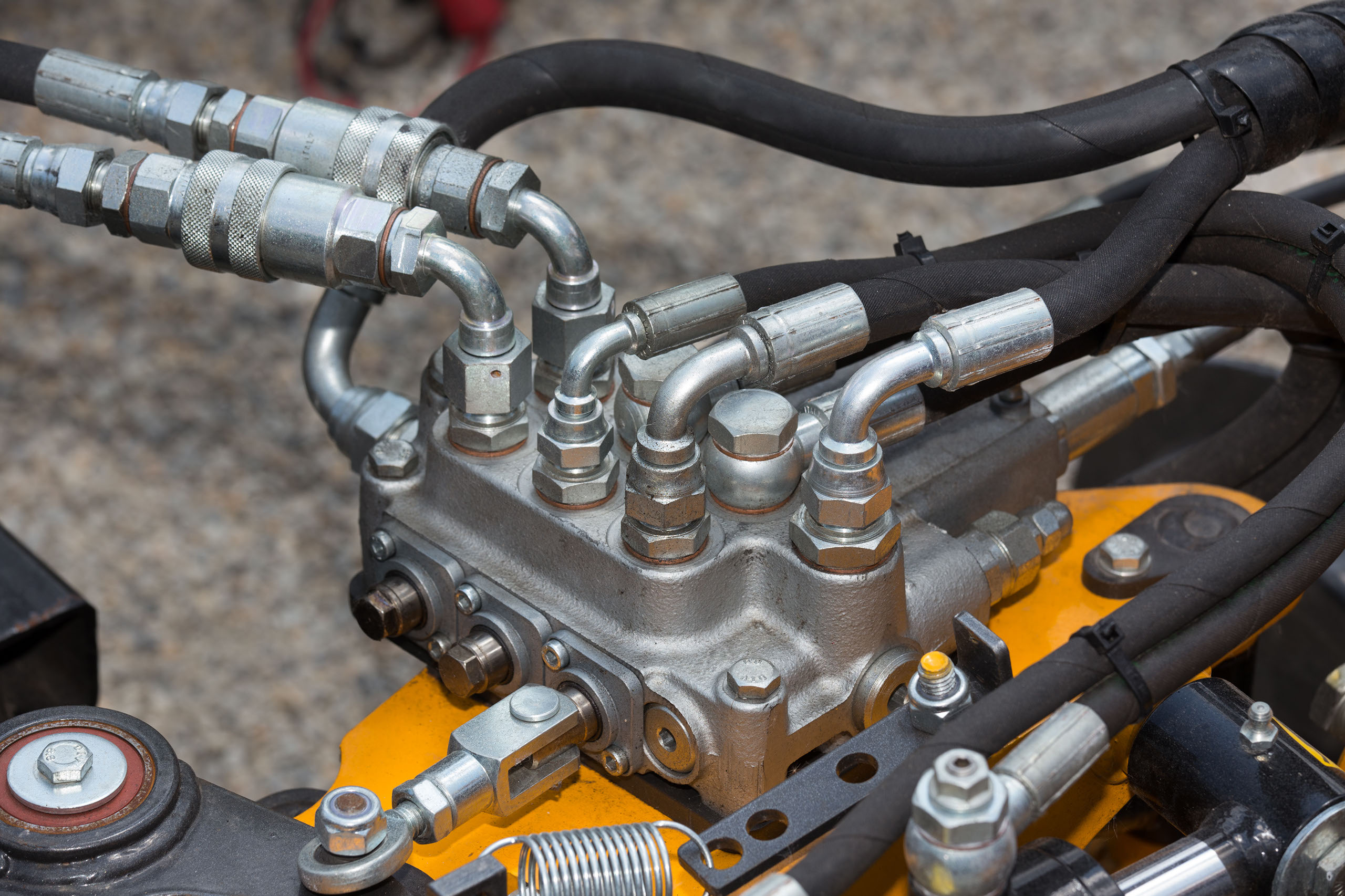

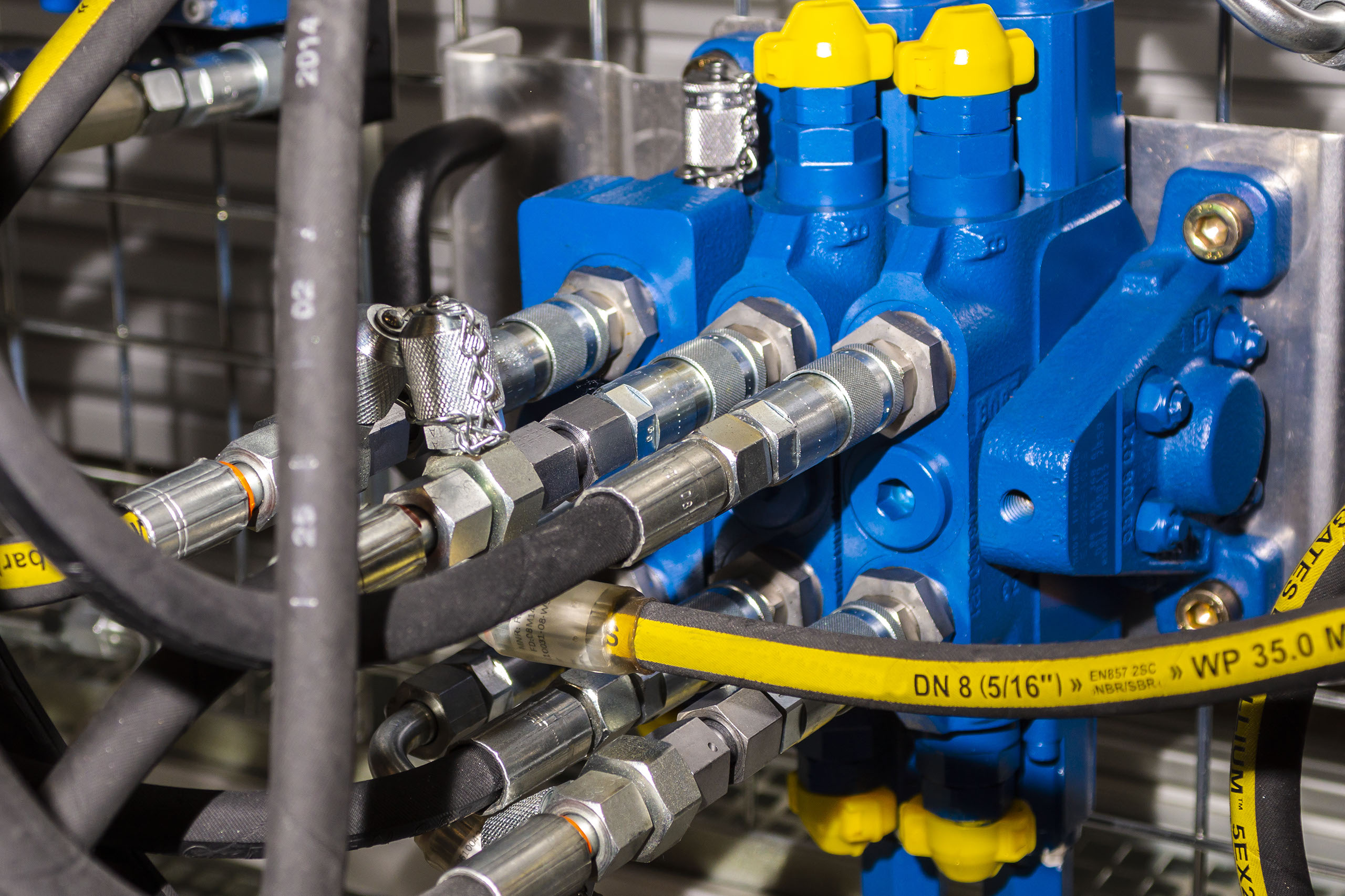

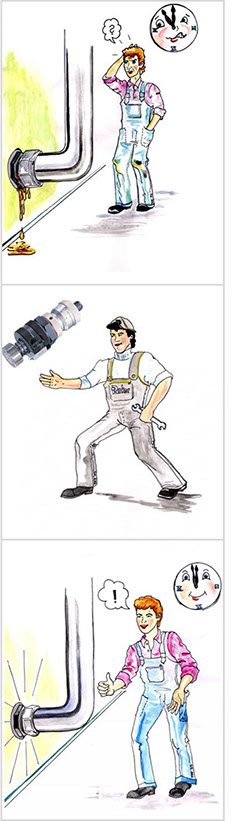

With the multicut*-precision tool, sealing areas in screw-in bores can be made or repaired in accordance with ISO 1179-1/ DIN 3852-2; ISO 9974-1/DIN 3852-1.

The unique working principle of the multicut* - *precision tool is exactly intended for the middle axis of the screw-in bore via the threaded sides and is ready for use in less than a minute

The micrometer screw with a 1/100 mm spacing additionally incorporated into the tool allows controlled depth adjustment of the removable profile steel, which can be individually profiled for manufacturing special sealing surfaces if needed.

The design of the threaded shaft counteracts the introduction of chips that occurs while machining the flattened sealing surface in the hydraulics cycle and allows the occasional machining of sealing surfaces in already “filled” but pressure-less hydraulic systems if the user takes the necessary precautions.

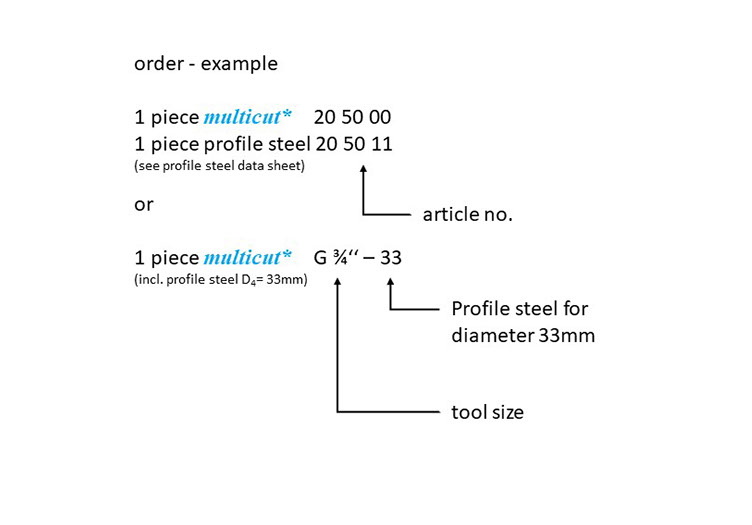

The multicut* - precision tools and the necessary profile steels are individually available in all standard sizes corresponding to ISO 1179-1/DIN 3852-2; ISO 9974-1/DIN 3852-1 of screw-in bores from G 1/8’’ to G 2’’ and from M 10 x 1 to M 78 x 2 or in the practical outdoor case.

For machining sealing surfaces, a multicut* precision tool that fits the screw-in bore thread and a correspondingly suitable multicut*-profile steel are needed.

The multicut* precision tool is designed for the use of exchangeable cutting bodies (profile steels).

The profile steel is not included in the scope of delivery of a multicut* precision tool and we ask you to select and order it separately.

Contact:

REINHARD Feinmechanik GmbH

Assar-Gabrielsson-Str. 1

63128 Dietzenbach

Germany

Tel: +49 (0)6074 84127 0

Fax: +49 (0)6074 2020

info@reinhard-feinmechanik.de

Our offer is aimed only at business customers!

(B2B Shop)

Would you like to send a message?